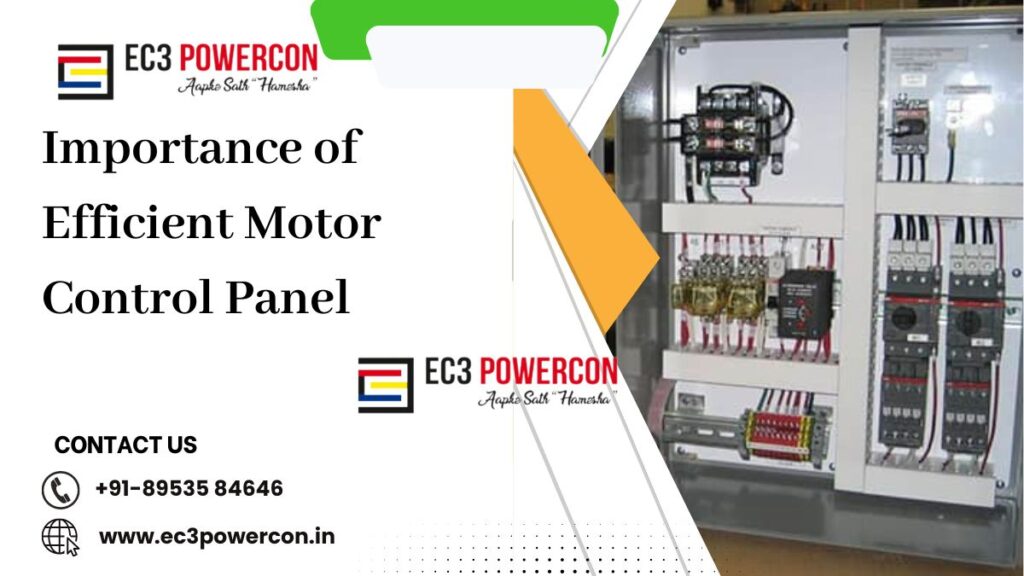

The Motor Control Panel is effectively used with motors or submersible pumps to provide sufficient protection from overloads and short circuits. These are high on performance, require low maintenance and can withstand extreme temperature variations.

AREA OF APPLICATION: Motor Control Centre: MCC panels are used in a wide range of industrial and commercial applications, including manufacturing plants, water treatment facilities, petrochemical plants, and buildings with extensive HVAC systems.

Table of Contents

What are the Motor Control Panel?

Motor Control Center (MCC) panels are the backbone of industrial electrical systems. In this blog post, we’ll delve into the intricacies of MCC panels, exploring their function, components, design considerations, and the vital role they play in powering industrial machinery. Whether you’re an engineer, technician, or simply curious about electrical systems, this guide will shed light on the powerhouses that keep industries running smoothly.

Understanding Motor Control Center (MCC) Panels: Motor Control Center (MCC) panels are centralized units designed to control and distribute electrical power to industrial motors and machinery. They serve as the nerve centre of a facility’s electrical system, providing a safe and efficient means of starting, stopping, and regulating motors across various applications.

Components of MCC Panels:

- Incoming Power Supply: MCC panels receive power from the main electrical supply of the facility, typically through circuit breakers or switchgear.

- Motor Starters: These devices control the operation of motors by providing the necessary voltage and current to start, stop, and regulate their speed. Motor starters may include contactors, overloads, and motor protection relays.

- Control Devices: MCC panels are equipped with control devices such as push buttons, selector switches, and pilot lights for manual operation and monitoring of motor functions.

- Protection Equipment: To ensure the safety of personnel and equipment, MCC panels incorporate various protection devices, including circuit breakers, fuses, and ground fault protection.

- Busbars and Wiring: Busbars and wiring within the MCC panels facilitate the distribution of electrical power to individual motor starters and other components.

- Enclosure: MCC panels are housed in sturdy enclosures made of materials such as steel or aluminium to protect against environmental factors and electrical hazards.

Features

- Remote control operation facility

- MCCB for protection

- Change over switch for circuit change from mains to DG and vice-versa

- Direct online starters that include MCB, contactor, thermal overload relay and connectors.

- Bus Bars of proper rating duly covered with an acrylic sheet for safety.

- Aluminium strip for earthing

- Panel light and fan for ventilation.

- Many more features that solve many practical problems.

Applications of MCC Panels:

MCC panels find widespread use across various industries and applications, including manufacturing, oil and gas, water treatment, mining, and commercial buildings. They are indispensable in controlling motors for pumps, compressors, conveyors, fans, and other critical machinery that drives industrial processes.

Design Considerations for the MCC Panels:

- Load Requirements: The design of MCC panels must accommodate the power requirements of the motors and machinery they control, including factors such as voltage, current, and frequency.

- Space Constraints: MCC panels are often installed in compact spaces, requiring careful consideration of size, layout, and accessibility during the design phase.

- Safety Standards: Compliance with industry standards and regulations, such as those outlined by the National Electrical Manufacturers Association (NEMA) and the International Electrotechnical Commission (IEC), is essential to ensure the safety and reliability of MCC panels.

- Ease of Maintenance: Designing MCC panels with accessibility features, modular components, and clear labelling simplifies maintenance tasks and minimizes downtime during troubleshooting and repairs.

- Scalability: As industrial operations evolve and expand, MCC panels should be designed with scalability in mind, allowing for the addition of new motor starters and control devices as needed.

Conclusion :

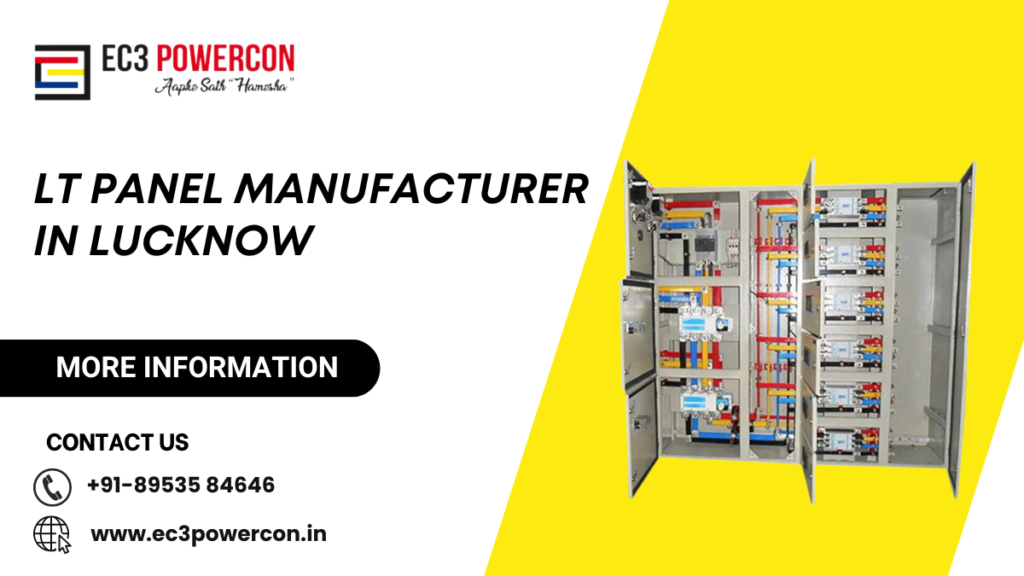

In the bustling industrial landscape of Lucknow, EC3 POWERCON emerges as a beacon of reliability and innovation. Choosing EC3 POWERCON as your Motor Control Center (MCC) panel manufacturer is not just a decision for today; it’s an investment in the future of your business. Experience the power of seamless automation with EC3 POWERCON, where quality meets innovation, and customer satisfaction is paramount.